We provide a detailed collection of spring design programs to improve your project, if you need it produced to fit your model, painting or measurements or whether you need us to help you create or test your company. At Adwin Laser we specialise in providing high-quality, reliable laser machines for use in a multitude of operations. We are able to provide laser machines to cover a vast amount of requirements, but if you are not sure what you need, feel free to speak to us. We specialise in both prototype and short-term production here at Adwin Spring, which will help you move your project forward. This state-of-the-art technology working side by side with a number of our more conventional ways of production, allows us to use all the abilities of our springs suppliers to assist us to produce the next product price. Whatever your demands for springs and pressed components, we are able to guide you for everything from repairs to development, small batches of prototypes or larger production quantities, from 1 spring to 1 million. Each request we accept and each order provides the identical professional service. We deal with specialist small volume finishers and offer a wide range of plating and plastic coating finishes so you get your parts ready to use.

Sandwell, United Kingdom

Founded in 1958

11-50 Employees

Working industry

Manufacturing

Type of company

Manufacturer

Ownership structure

Privately Held

Locations

1 Headquarter

Number of products

6 Products

Specialised areas

Manufacturing, Electronic Components, CNC, Mechanical Or Industrial Engineering, Wire Springs, Power Press, Engineering, CAD, ISO9001, Prototyping Development

Adwin Spring Co Ltd offers a wide range of products and services

Product

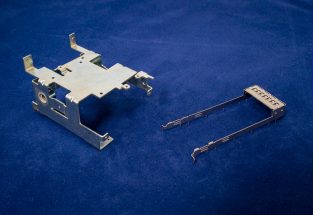

Flat Springs - Laser Cutting And Marking - Adwin

Go to product >

Product

The Best Wire Springs in UK - Adwin

Go to product >

Product

Our Products

Go to product >

Product

Pressings - Power Press Capacity - Adwin

Go to product >

Product

Electronic Components High Precision in UK - Adwin

Go to product >

Product

Technologies - WAFIOS SPRING COILING MACHINES

Go to product >

An estimation about the ESG values based on digital data and signals. Important: The ESG scores are only based on information about the country, not the actual company itself

Country:

United Kingdom

Overall risk estimation:

Very low

The ESG Data of countries are based on public sources

Environment

A

Grade (A-E)

View details

Social

A

Grade (A-E)

View details

Governance

A

Grade (A-E)

View details

Adwin Spring Co Ltd operates in 1 country around the world

Get an overview of the locations of Adwin Spring Co Ltd

Location

Country

State

City

Headquarter

United Kingdom

England

Sandwell

Some frequent questions that have been asked about Adwin Spring Co Ltd

Where is Adwin Spring Co Ltd located?

The company headquarter of Adwin Spring Co Ltd is located in Sandwell, England, United Kingdom. It's worth noting, that the company may have more locations

How many employees does Adwin Spring Co Ltd approximately have?

As of the latest available information Adwin Spring Co Ltd has around 11-50 employees worldwide.

When was Adwin Spring Co Ltd founded?

Adwin Spring Co Ltd was founded in 1958

In which industries does Adwin Spring Co Ltd mainly work?

The company Adwin Spring Co Ltd has it's main focus in the industries of Manufacturing

Check out some interesting alternative companies to Adwin Spring Co Ltd

Tadd Spring Company

Strongsville, United States

11-50 Employees

1963

Our vision is to supply springs faster, better, and at a more reasonable cost. We are experts in custom precision spring manufacturing; from prototyping to large production runs with very short lead times, in-house finishing capabilities, and packaging solutions available. Original equipment manufacturers choose us as their trusted, full-service spring supplier for oil pump priming, pressure relief, fuel systems, transmissions, hydraulics, pneumatic valves and more. Our customers love working with us because we produce high quality products with proven reliability. We can assist with all aspects of spring manufacturing including design, prototyping, testing, production optimization, and more. Our management team has over 150 years combined spring manufacturing experience. To stay on top, we’ve partnered with the Spring Manufacturing Institute and various field professionals to make sure everything we produce represents the quality and responsible manufacturing process we believe in. We have strict standards when it comes to our manufacturing process and never settle for less.

Reiner Schmid Produktions GmbH

Germany

1-10 Employees

-

Our company specializes in designing, developing and manufacturing innovative and precise technical metal springs such as special springs, special springs, torsion springs, double torsion springs, bent wire parts or stamped bent parts that meet individual customer requirements. Our expertise and strengths: We have many years of experience and comprehensive know-how in the development and manufacture of metal special springs and special springs. We understand the challenges our customers face and apply our expertise to deliver innovative spring solutions. That is why we offer tailor-made metallic special springs that are precisely tailored to the needs of our customers. Latest manufacturing technologies: Our company relies on the latest manufacturing technologies to ensure the highest level of precision and quality. We have advanced CNC bending machines, automated production systems, and computerized quality assurance procedures that ensure consistently high product quality. Our modern facilities enable us to efficiently realize complex shapes, tight tolerances and high production volumes. We offer a comprehensive and customer-oriented service that ranges from advice, calculation and design to delivery and after-sales support.

Ibumedia GmbH

Obermichelbach, Germany

1-10 Employees

-

Our company specializes in designing, developing and manufacturing innovative and precise technical metal springs such as special springs, special springs, torsion springs, double torsion springs, bent wire parts or stamped bent parts that meet individual customer requirements. Our expertise and strengths: We have many years of experience and comprehensive know-how in the development and manufacture of metal special springs and special springs. We understand the challenges our customers face and apply our expertise to deliver innovative spring solutions. That is why we offer tailor-made metallic special springs that are precisely tailored to the needs of our customers. Latest manufacturing technologies: Our company relies on the latest manufacturing technologies to ensure the highest level of precision and quality. We have advanced CNC bending machines, automated production systems, and computerized quality assurance procedures that ensure consistently high product quality. Our modern facilities enable us to efficiently realize complex shapes, tight tolerances and high production volumes. We offer a comprehensive and customer-oriented service that ranges from advice, calculation and design to delivery and after-sales support.

Betts Spring Manufacturing

Fresno, United States

51-100 Employees

1868

Looking for a proprietary spring design for your custom application? Contact us today to work with our dedicated spring engineering team for insight on precision specs and tolerance, spring rate, load rate and stability. Your customers demand quality springs that meet or exceed their (and your) expectations. Delivering the highest quality products starts with precision processing in accordance with ISO:9001 standards. The result: Consistently performing products that you and your customers love. From he highest performing cold wound and hot wound coil springs, along with leaf springs, our dedicated teams can design and produce it all under one roof.

J T Pearce Springs

Redditch, United Kingdom

1-10 Employees

-

We are always happy to work from drawings or CAD data. Customers have been benefiting since 1998 from a fast turn around and high quality product from an established family business. Swift expert advice solutions and production from a family run firm with a central UK location. With a lean manufacturing culture J T Pearce (Springs) is able to offer a rapid prototyping service and bring to bear many years experience to enable a quick and thoughtful response. From the earliest stages of spring design and materials specification, through to prototype and pre-production manufacture. Once your product is ready for volume production we are able to produce modest to medium sized quantities very competitively.

Adlaser Profiles

Southampton, United Kingdom

1-10 Employees

-

We are able to offer a complete service from CAD/CAM Design, through to laser cutting, press brake folding and final finishing. Our operatives are fully trained in all of the services that we offer and we continually strive to meet our customers’ expectations in terms of price, lead times and quality of product and workmanship. Upon request a 24-48 hour turnaround can be offered subject to specification. Adlaser’s integration of CAD and CAM is the reason why we can create your unique parts quicker and to a clear deadline. In-house design & drafting services to assist your development, evaluation and manufacturing needs. In house wet spray and powder coating facilities to finish your products.